Welcome to

MSM PROCESS SOLUTIONS PVT. LTD.

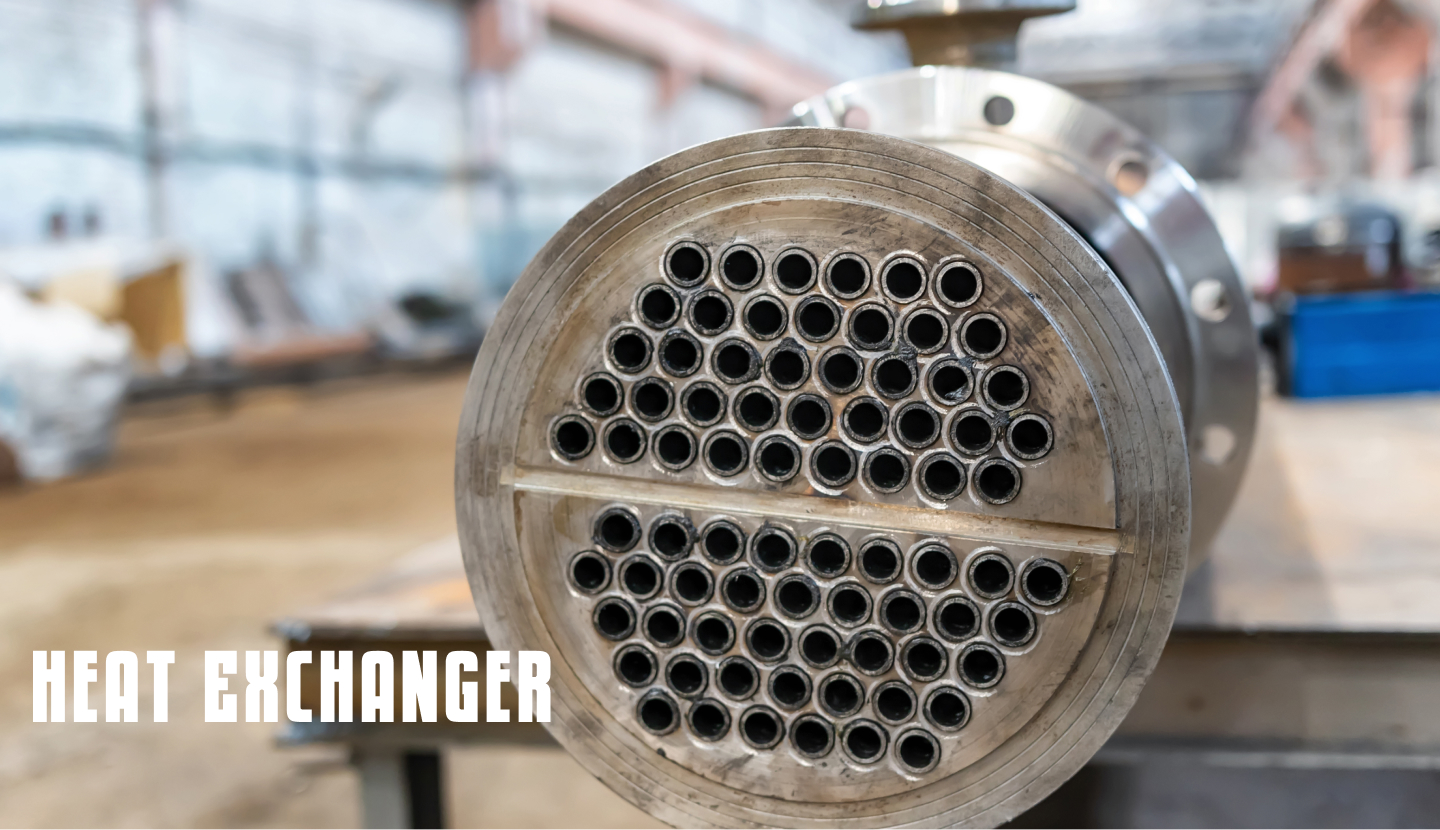

Sturdy, Affordable and Tested CIP SIP Modules, Contra Rotary Mixer, Paste Kettle, SS Agitator, Heat

Exchanger, Bio Fermenter, Mixer Tank, Automatic Ointment Plant, etc.

In the domain of pharmaceutical and medicine manufacturing, efficiency, precision, and hygiene are the important factors to adhere to.

Various equipment and components play crucial roles in maintaining the quality standards and consistency of pharmaceutical products.

To develop effective and quality-tested medicines, different pharmaceutical production equipment is used, such as CIP SIP Modules, Contra Rotary Mixers, Paste Kettles, SS Agitators, Heat Exchangers, Bio Fermenters, Mixer Tanks, Automatic Ointment Plants, etc.

To develop effective and quality-tested medicines, different pharmaceutical production equipment is used, such as CIP SIP Modules, Contra Rotary Mixers, Paste Kettles, SS Agitators, Heat Exchangers, Bio Fermenters, Mixer Tanks, Automatic Ointment Plants, etc.

Our Products

Sterile Blending Vessel

Manufacturer and Supplier for heavy-duty and affordable products Etc.

Our Infrastructural Base

Our company has a modern infrastructural base with advanced facilities

and tools to design high-quality CIP SIP Modules, Contra Rotary

Our Team

We have recruited a team of engineers and designers to create a

high-quality array of CIP SIP modules, including the Contra Rotary Mixer, Paste

Major Markets

Our company has spread its wings across the global market to

meet the different demands of our clients with the best. We have developed

REASONS TO BUY TO US

Contact us now

Contact us now

Enquire now

Please take a moment to complete this form and a business representative will get back to you swiftly.

Get a quote

Get a quote